Centerless grinding wheel

Price 3200.00 INR/ Box

MOQ : 1 Box

Centerless grinding wheel Specification

- Toughness

- High toughness for continuous grinding applications

- Backing

- None (solid wheel)

- Hardness

- H to Q

- Grain Type

- A (Aluminum Oxide), C (Silicon Carbide)

- Shape

- Round / Cylindrical

- Bonding

- Vitrified / Resinoid

- Chemical Composition

- Al2O3 or SiC, vitrified or resinoid bonding agent

- Material

- Aluminum Oxide / Silicon Carbide

- Type

- Centerless Grinding Wheel

- Grain Sizes

- 16 to 120 (mesh grit)

- Rolls Size

- 350 mm to 700mm

- Strips Size

- Custom / As per requirement

- Max Operating Speed

- Up to 1900 RPM

- Color

- Grey / Green (varies with grit type)

- Manufacturing Standard

- Conforms to ISO and industry specific standards

- Precision

- High dimensional accuracy and surface finish

- Application

- Centerless cylindrical grinding for bars, tubes, components, and shafts

Centerless grinding wheel Trade Information

- Minimum Order Quantity

- 1 Box

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cheque

- Delivery Time

- 2 Days

- Packaging Details

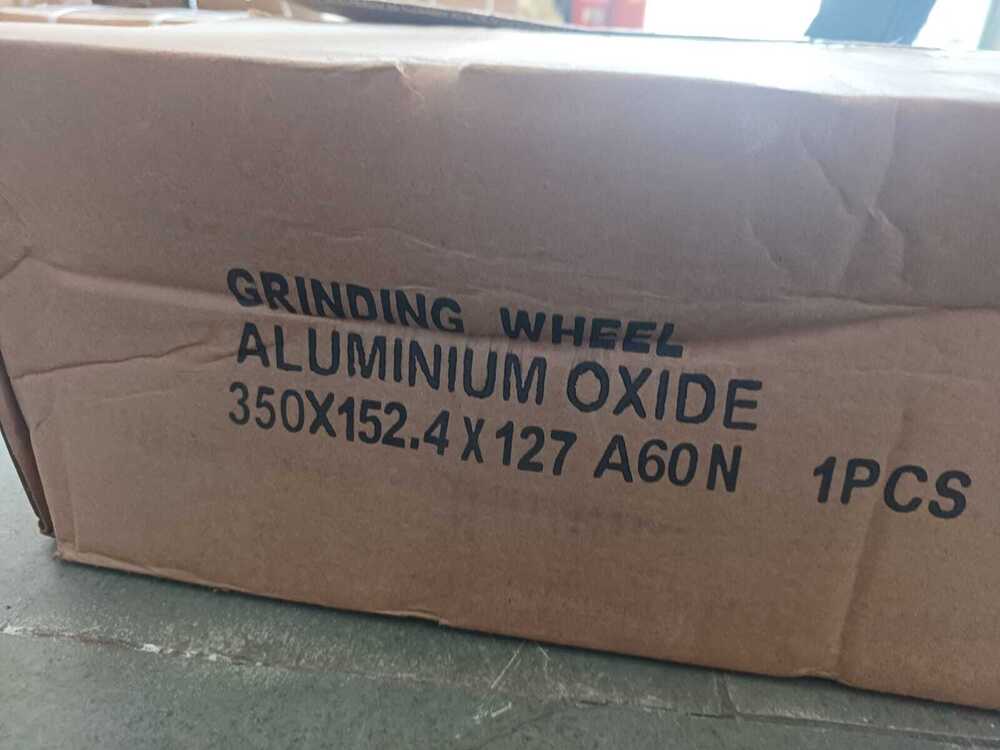

- 1 PC CARTOON , THARMOCOL PACKING

- Main Domestic Market

- All India

About Centerless grinding wheel

Centerless Grinding Wheel 350X152.4X127 A60 ,A80 ,A463 .The centreless wheels we are offering are manufactured under the guidance of experienced professionals, in accordance with the norms of the industry. While manufacturing these wheels, these professionals make use of high quality material and employ latest technology. We also offer customized range of these centreless wheels as per the requirement of the customers.Unmatched Precision and Versatility

Engineered for centerless grinding of a broad range of materials, this wheel delivers tight tolerances and excellent surface finishes. Its advanced grain types and wide mesh grit options accommodate various applications, making it suitable for both rough and fine grinding tasks.

Built for High-Performance Operations

With a robust design supporting grinding speeds up to 1900 RPM and a flexible grinding length (350 mm to 700 mm), this wheel is ideal for continuous, heavy-duty use. Both vitrified and resinoid bonds impart stability and durability, ensuring reliable performance in industrial settings.

Customization to Match Every Requirement

Available in Aluminum Oxide and Silicon Carbide, as well as multiple hardness grades (H to Q), these wheels can be tailored to specific production needs. The option to customize strip size and choose between round or cylindrical shapes allows for seamless integration into various grinding setups.

FAQ's of Centerless grinding wheel:

Q: How is the centerless grinding wheel utilized in different industries?

A: The wheel is used for centerless cylindrical grinding of bars, tubes, shafts, and other components requiring high precision. Industries such as automotive, aerospace, machinery manufacturing, and metal processing rely on its efficiency for both roughing and finishing operations.Q: What benefits does this grinding wheel offer in terms of precision and surface finish?

A: Designed to deliver high dimensional accuracy and an excellent surface finish, the wheel's premium grains and strong bonding support consistent results, reducing the need for secondary machining operations and improving overall productivity.Q: When should you choose Aluminum Oxide over Silicon Carbide grain type?

A: Aluminum Oxide (type A) is preferred for grinding ferrous materials, offering high toughness and long life. Silicon Carbide (type C) is ideal for non-ferrous metals and hard materials, delivering faster cutting action but with slightly lower durability.Q: Where is this centerless grinding wheel distributed and supplied?

A: This wheel is readily available across India through an extensive network of distributors, importers, and wholesalers, ensuring prompt delivery and reliable technical support nationwide.Q: What is the standard process for selecting the right grinding wheel size and grit?

A: Selection depends on the application's requirements-choose grit size (16 to 120 mesh) based on the desired surface finish, wheel size according to workpiece dimensions (350x152x127 mm standard, with grinding lengths from 350 mm to 700 mm), and material compatibility with specific bonding agents and grains.Q: How does the grinding wheel conform to quality and safety standards?

A: Each wheel is manufactured adhering to ISO and industry-specific standards, guaranteeing safety, consistency, and performance at maximum operating speeds up to 1900 RPM.Q: What process should be followed for optimal grinding wheel usage and longevity?

A: To maximize life and efficiency, ensure compatibility with your grinding setup, use recommended speeds, regularly inspect for wear, and select the right bond and grit for your specific application. Proper handling and storage are also crucial to maintain wheel integrity.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Centerless Grinding Wheel Category

Grinding Wheel

Price 6700.00 INR / Box

Minimum Order Quantity : 1 Box

Backing : None (solid wheel)

Chemical Composition : Al2O3 or SiC, bonding agents

Grain Sizes : 24 to 120 mesh (as per requirement)

Type : Grinding Wheel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free