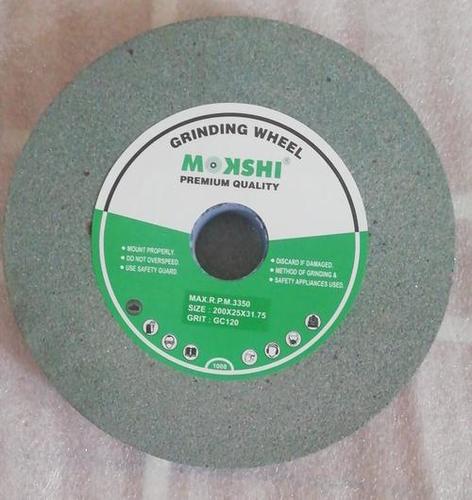

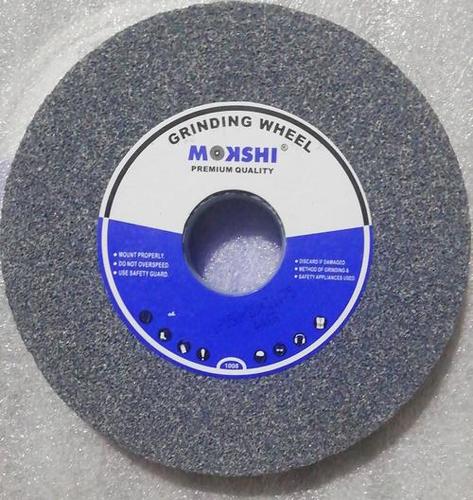

Grinding Wheel

Grinding Wheel Specification

- Machine Type

- Surface Grinder / Tool Grinder Compatible

- Coating Type

- Uncoated

- Hardness

- High

- Cutting Speed

- Up to 35 m/s (typical)

- Operate Method

- Mechanical rotation

- Operation Type

- Manual or Machine

- Cutting Force

- Standard

- Tool Type

- Grinding Wheel

- Features

- Durable construction, precision balanced, efficient grinding performance

- Length

- Varies (commonly 20 mm thickness)

- Cutting Accuracy

- High

- Diameter

- Approximately 200 mm

- Processing Type

- Grinding

- Bond Type

- Vitrified Bond

- Max Operating Speed

- 3600 RPM

- Application

- Surface grinding, tool sharpening, deburring

- Color

- Gray

- Package Includes

- 1 Grinding Wheel

- Abrasive Type

- Aluminum Oxide / Silicon Carbide (varies by use)

- Grit Size

- Medium (46 to 60 Grit, typical)

- Edge Type

- Straight

Grinding Wheel Trade Information

- Minimum Order Quantity

- 10 Pieces

- Delivery Time

- Immediate Seconds

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Box, Thermocol

- Main Domestic Market

- All India

About Grinding Wheel

Competitive Advantages & Areas of Application

Experience the crowning benefits of our grinding wheel-engineered for breathtaking accuracy in surface grinding, tool sharpening, and deburring processes. Its paragon construction ensures durability, a high cutting speed, and a standard cutting force ideal for mechanical workshops and tool rooms. This wheel is widely used for efficient finishing and refurbishing of metal surfaces, delivering consistent results whether used in manual operations or machine setups. Choose it for optimal grinding applications across multiple industries.

Supply Ability and Market Reach

We guarantee swift handover of our grinding wheels throughout the main domestic market, with prompt delivery to every region in India. Export market options are also available for international clients. Samples can be delivered for quality evaluation before bulk orders. As a trusted distributor, importer, and wholesaler, we take pride in reliable supply abilities, ensuring on-time product handover and consistent availability to support your production needs.

FAQ's of Grinding Wheel:

Q: How do I select the right abrasive type for my grinding application?

A: The abrasive type-aluminum oxide or silicon carbide-should be chosen based on your material. Aluminum oxide works well for steel and general grinding, while silicon carbide is ideal for non-ferrous metals and softer materials.Q: What benefits does the vitrified bond offer in this grinding wheel?

A: The vitrified bond provides excellent durability, thermal stability, and precise dimension control, making the grinding wheel suitable for both manual and machine operations with high reliability and longevity.Q: Where can this grinding wheel be used effectively?

A: This grinding wheel is ideal for use in workshops, tool rooms, and industrial settings for surface grinding, tool sharpening, and deburring tasks, compatible with both surface grinders and tool grinders.Q: What are the storage and handling recommendations for the grinding wheel?

A: Store the grinding wheel in a dry, cool place away from moisture and impacts. Handle with care to prevent cracks or damage prior to mounting on your equipment.Q: How does the high cutting speed benefit my grinding process?

A: With speeds up to 35 m/s, the wheel ensures efficient material removal and smooth finishing, saving time and delivering high cutting accuracy across various applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Grinding Wheel Category

Flap Wheel

Price 210 INR / Piece

Minimum Order Quantity : 10 Pieces

Operation Type : Other, Rotary

Features : Flexible, High Stock Removal, Consistent Finish

Cutting Force : Medium

Tool Type : Flap Wheel

Marble Cutter

Price 200.0 INR / Pack

Minimum Order Quantity : 20 Packs

Operation Type : Other, Electric

Features : Dust Proof, Ergonomic Design, Easy Grip, Portable, VibrationFree

Cutting Force : Low Force Required

Tool Type : Handheld Power Tool

150x20x31.75 A36 Grinding Wheel

Price 150 INR

Minimum Order Quantity : 10 Pieces

Operation Type : Other, Surface & Cylindrical Grinding

Features : High grinding efficiency, Durability, Precise finish

Cutting Force : Medium

Tool Type : A36 Grinding Wheel

150x20x31.75 A46 Grinding Wheel

Price 150 INR

Minimum Order Quantity : 10 Pieces

Operation Type : Other, Manual and Machine

Features : High durability, efficient material removal, consistent performance

Cutting Force : Medium

Tool Type : Abrasive Wheel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free