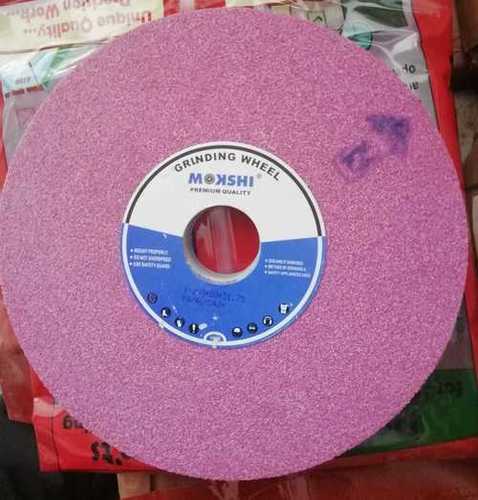

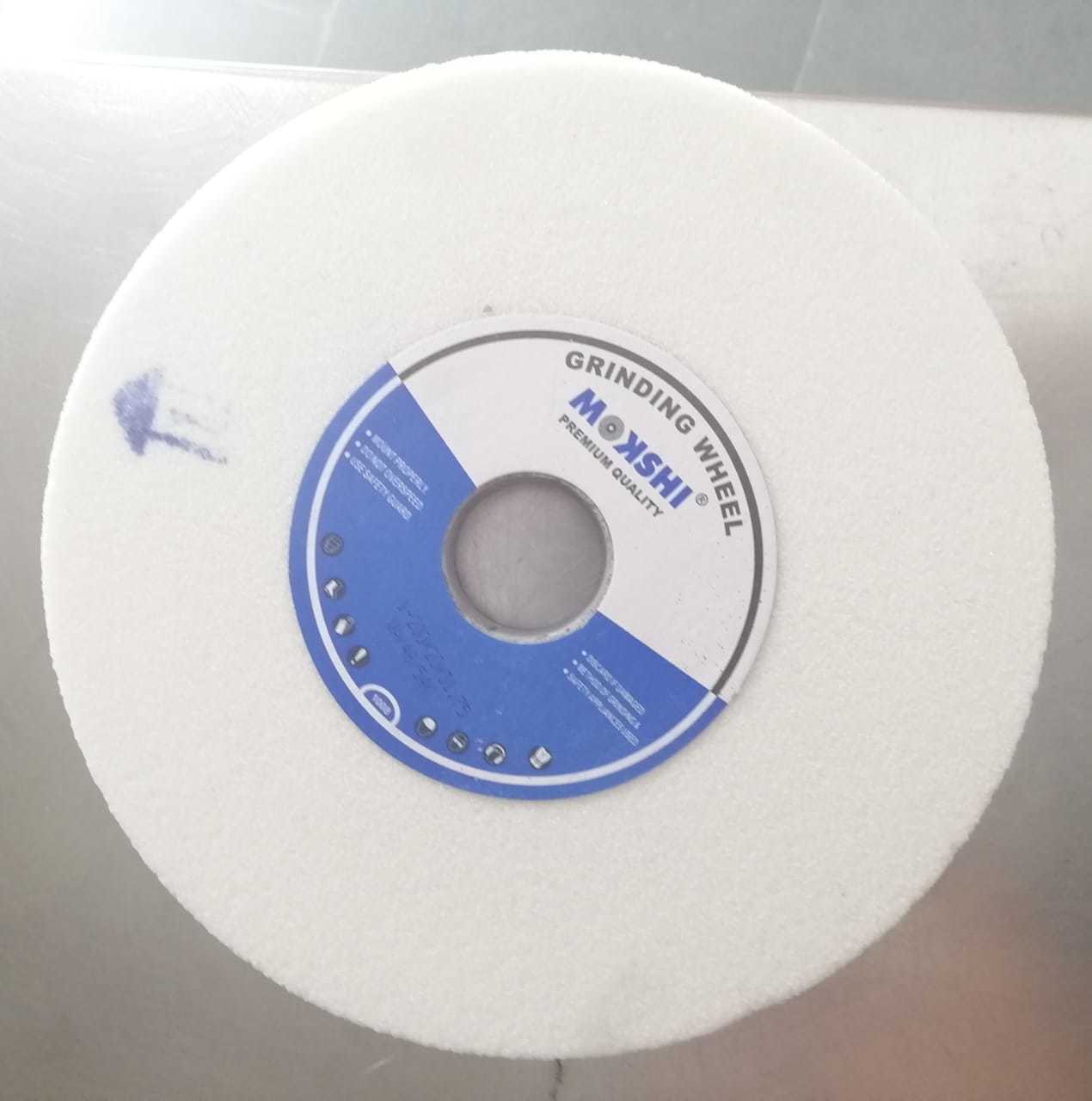

Surface Grinding Wheels

MOQ : 10 Pieces

Surface Grinding Wheels Specification

- Hardness

- Soft, Medium, Hard (varies as per application)

- Grain Type

- Aluminium Oxide, Silicon Carbide

- Bonding

- Vitrified, Resin

- Shape

- ROUND

- Toughness

- High

- Chemical Composition

- Aluminium Oxide/ Silicon Carbide with bonding agents

- Material

- ABRASIVE

- Type

- Surface Grinding Wheel

- Grain Sizes

- Fine/Medium/Coarse (varies from 36 to 600 grit)

- Rolls Size

- Customizable as per requirement

- Strips Size

- N/A for surface grinding wheels

- Application

- Tool room, Die shop, Industrial machining

- Maximum Operating Speed

- Up to 40 m/s

- Standards

- Compliant with IS: 551-1983/ISO standard

- Color

- Grey/White/Black (depends on grain and bond)

- Thickness

- 6 mm - 75 mm

- Wheel Structure

- Open/Closed (depending on required material removal rate)

- Usage

- Precision surface grinding for metals and non-metals

- Diameter

- 100 mm - 500 mm

Surface Grinding Wheels Trade Information

- Minimum Order Quantity

- 10 Pieces

- Payment Terms

- Cheque, Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Cash in Advance (CID), Cash Advance (CA)

- Delivery Time

- IMMEDIATE Hours

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- BOX, THERMOCOL

- Main Domestic Market

- All India

About Surface Grinding Wheels

Highlight your workshops efficiency with our grandiose Surface Grinding Wheels, crafted for brilliance and precision. Select from diameters ranging 100 mm to 500 mm and thicknesses from 6 mm to 75 mm, allowing you to grab the dominant solution for any grinding challenge. Suited for both metals and non-metals, each wheel features high toughness and comes in customizable sizes. Choose from Aluminium Oxide or Silicon Carbide, in round shape, and enjoy compliance with IS:551-1983/ISO standard for unrivaled safety and performance in industrial machining, tool rooms, and die shops.

Competitive Advantages and Application Method

Our Surface Grinding Wheels outshine the competition by delivering exceptional precision and longevity. Frequently utilized by tool rooms, die shops, and industrial machinists, these dominant wheels ensure consistent surface quality. Users simply mount the wheel, align with the workpiece, and operate at up to 40 m/s for magnificent material removal. The customizable structureopen or closedlets users select the optimal rate, making these wheels highlighted tools in any demanding environment.

Certifications, Export Markets, and Delivery Terms

Our Surface Grinding Wheels adhere strictly to IS:551-1983/ISO standards, offering assurance of superior quality and operational safety. These brilliant wheels are delivered from major Indian seaports following a confirmed purchase order. With a dominant presence in both the domestic market and international export sectors, we cater to clients worldwide by ensuring timely shipments and rigorous compliance with required certifications. FOB terms provide added flexibility for international buyers.

Competitive Advantages and Application Method

Our Surface Grinding Wheels outshine the competition by delivering exceptional precision and longevity. Frequently utilized by tool rooms, die shops, and industrial machinists, these dominant wheels ensure consistent surface quality. Users simply mount the wheel, align with the workpiece, and operate at up to 40 m/s for magnificent material removal. The customizable structureopen or closedlets users select the optimal rate, making these wheels highlighted tools in any demanding environment.

Certifications, Export Markets, and Delivery Terms

Our Surface Grinding Wheels adhere strictly to IS:551-1983/ISO standards, offering assurance of superior quality and operational safety. These brilliant wheels are delivered from major Indian seaports following a confirmed purchase order. With a dominant presence in both the domestic market and international export sectors, we cater to clients worldwide by ensuring timely shipments and rigorous compliance with required certifications. FOB terms provide added flexibility for international buyers.

FAQs of Surface Grinding Wheels:

Q: How are the sizes of surface grinding wheels selected for different grinding applications?

A: The wheel size depends on the machines spindle and the specific application. Diameters range from 100 mm to 500 mm, and thickness varies between 6 mm to 75 mm, allowing you to select the most suitable wheel for tool rooms, die shops, or industrial machining tasks.Q: What is the process for customizing the surface grinding wheels?

A: Customization is simple: upon receiving your specifications, we manufacture the wheels according to your required diameter, thickness, bond type, and grain size, ensuring the product is tailored precisely to your usage needs.Q: Where are these surface grinding wheels commonly used?

A: These surface grinding wheels are commonly used in tool rooms, die shops, precision engineering establishments, and industrial machining facilities requiring efficient and accurate surface finishing for both metals and non-metals.Q: What are the main benefits of using vitrified or resin-bonded surface grinding wheels?

A: Vitrified bonds provide grandiose rigidity and heat resistance, perfect for high-precision grinding, while resin bonds deliver superior shock absorption and adaptability, making them suitable for less rigid setups and smoother finishes.Q: When should I choose an open versus a closed wheel structure?

A: An open structure is ideal when you want higher material removal rates and cooler operations, especially for softer materials. Closed structures are selected when a smoother finish and slower material removal are essential.Q: How does the grain type and hardness relate to different grinding materials?

A: Aluminium Oxide is dominant for ferrous metals, while Silicon Carbide is highlighted for non-ferrous and non-metallic materials. Hardness can be soft, medium, or hardselected based on the workpiece to optimize performance and wheel longevity.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS