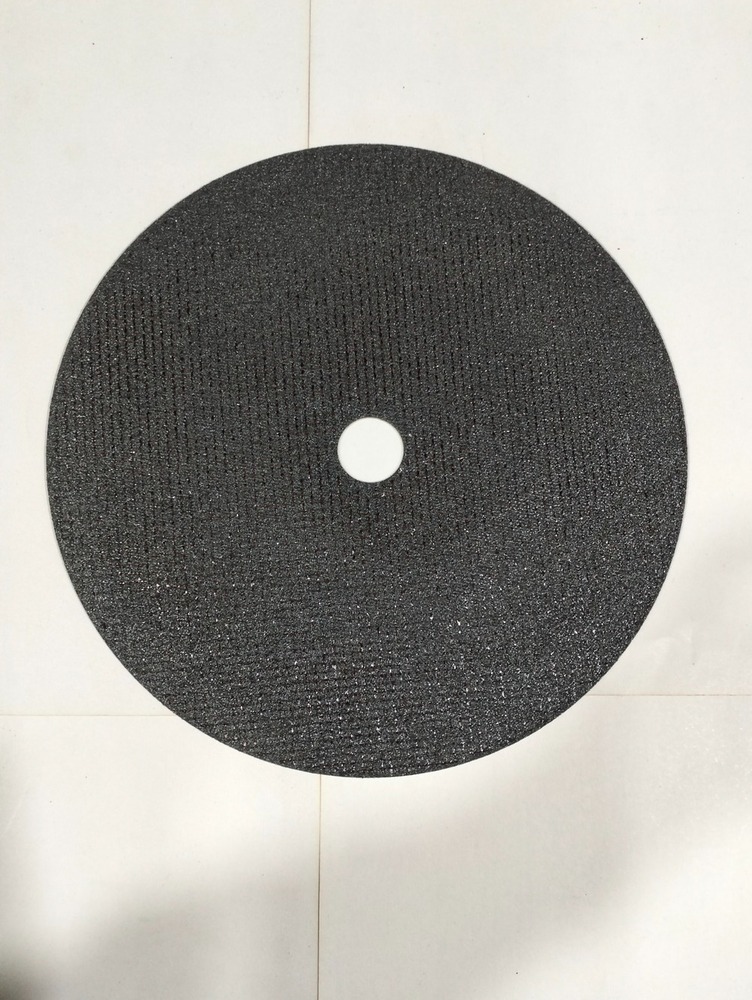

10 INCH CUT OFF WHEEL

Price 60.00 INR/ Piece

10 INCH CUT OFF WHEEL Specification

- Hardness

- Rigid

- Shape

- ROUND

- Backing

- Double net

- Usage

- Industrial , special stanless steel

- Material

- Reinforced Resin Bonded (Aluminium Oxide/SiC blend)

- Type

- Abrasive Cutting Wheel

- Size

- 250X1.5X25.4

- Height

- 1.5 Millimeter (mm)

- Grain Sizes

- WA46

- Product Type

- Cutting Wheel

- Rolls Size

- 100 mm, 125 mm, 180 mm, 230 mm, 250mm ,300 mm, 355 mm, and custom sizes available

- Color

- BLACK

- Length

- 250 Millimeter (mm)

- Width

- 25.4 Millimeter (mm)

10 INCH CUT OFF WHEEL Trade Information

- Minimum Order Quantity

- 50 Pieces

- Delivery Time

- 5 Days

- Main Domestic Market

- All India

- Certifications

- CUTTING WHEEEL USE FOR MS, SS, CAST AND OR CUTTING THICKNESS 3 HEAVY MATERIEAL CUT OR DIAMATER 400MM CUTTING WHEEL SPECIAL SS CUTTING OR SS ROUNDBAAR , SS PIPE, SSBAR ALL CUTTING SPEED CUT

About 10 INCH CUT OFF WHEEL

We are considered to be one of the most important suppliers ofReinforced Cutting Wheelsin the domestic market. In order to fulfill the rising demands of the market, we have come forward to present a capacious range of wheels for our diverse clients. Our offeredReinforced Cutting Wheelsfind wide application in various industries and are fitted in various cutting machines for grinding alloys, mild steel, stainless steel and cast iron.

Features

- Reliable & sturdy construction

- Less heat generation

- Immaculate accuracy

Reinforced Cutting Wheels

We offer high grade of Abrasive Cutting Wheels. These are manufactured by using optimum grade raw material. These are ideal for grinding alloys, stainless steel, mild steel and cast iron. These have great strength reliable sturdy construction high durability. Avail as per specification of client at reasonable market prices.

Exceptional Durability for Industrial Applications

Built with reinforced resin bonded material and double net backing, the 10 Inch Cut Off Wheel stands up to demanding industrial use. It easily cuts special stainless steel, ensuring higher productivity and reduced downtime. The rigid construction promotes stability during high-speed cutting.

Versatile Sizing and Customization

Available in popular sizes (100 mm up to 355 mm) and custom options, this abrasive cutting wheel fits various machines and projects. Whether for large-scale manufacturing or custom fabrication, users can rely on its compatibility and adaptability to meet specific requirements.

FAQ's of 10 INCH CUT OFF WHEEL:

Q: How should the 10 Inch Cut Off Wheel be properly installed?

A: Ensure that the wheel is securely mounted on the appropriate cutting machine with a compatible arbor size (25.4 mm). Follow safety procedures by checking for cracks or defects, and always use recommended personal protective equipment.Q: What materials can this abrasive wheel cut through effectively?

A: This wheel is specifically designed for industrial-grade cutting of special stainless steel, but its reinforced resin bond with aluminium oxide and silicon carbide blend also enables it to handle a wide range of ferrous and non-ferrous metals.Q: When should I replace the 10 Inch Cut Off Wheel?

A: Replace the wheel when you notice visible wear, reduced cutting efficiency, or if the blade is cracked or warped. Regular inspection before each use is essential for safe operation.Q: Where can I purchase or source this cutting wheel in India?

A: You can procure the 10 Inch Cut Off Wheel through authorized distributors, importers, or wholesalers across India. Custom sizing can also be requested based on your industrial needs.Q: What is the manufacturing process behind this abrasive cutting wheel?

A: The wheel is produced using a reinforced resin bond that combines aluminium oxide and silicon carbide. It is structured with a double net backing for added strength and pressed into a rigid round shape, followed by precision curing.Q: How does the double net backing benefit users?

A: The double net backing enhances the wheel's stability and durability, reducing the risk of breakage during intense operations and providing smoother, safer cuts.Q: What advantages does the WA46 grain size deliver for cutting?

A: The WA46 grain size ensures optimal balance between material removal and surface finish, making it efficient for high-precision and fast cutting, particularly in special stainless steel applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Reinforced Cutoff Wheels Category

14 CUT OFF WHEEL

Price 85.00 INR / Piece

Minimum Order Quantity : 100 Pieces

Shape : ROUND

Material : Reinforced Resin Bonded (Aluminium Oxide/SiC blend)

Type : Abrasive Cutting Wheel

Size : 355X2.5X25.4

CUTTING WHEEL

Price 7.00 INR / Piece

Minimum Order Quantity : 50 Pieces

Shape : ROUND

Material : High Speed Steel

Type : Abrasive Cutting Wheel

Size : 107X1X16

CUT OFF WHEEL

Price 52.00 INR / Piece

Minimum Order Quantity : 50 Pieces

Shape : ROUND

Material : Carbide, High Speed Steel, Tungsten Cobalt Alloy, Steel, Hard Alloy, Tungsten Carbide, Stainless Steel, Alumina, Metal, Carbon Steel, Chrome Vanadium, Cobalt Alloy

Size : 250X1.5X25.4

7 INCH CUTTING WHEEL

Price 32.00 INR / Piece

Minimum Order Quantity : 200 Pieces

Shape : ROUND

Material : Aluminum Oxide

Type : Metal cutting wheel

Size : 180x1.2x22

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free