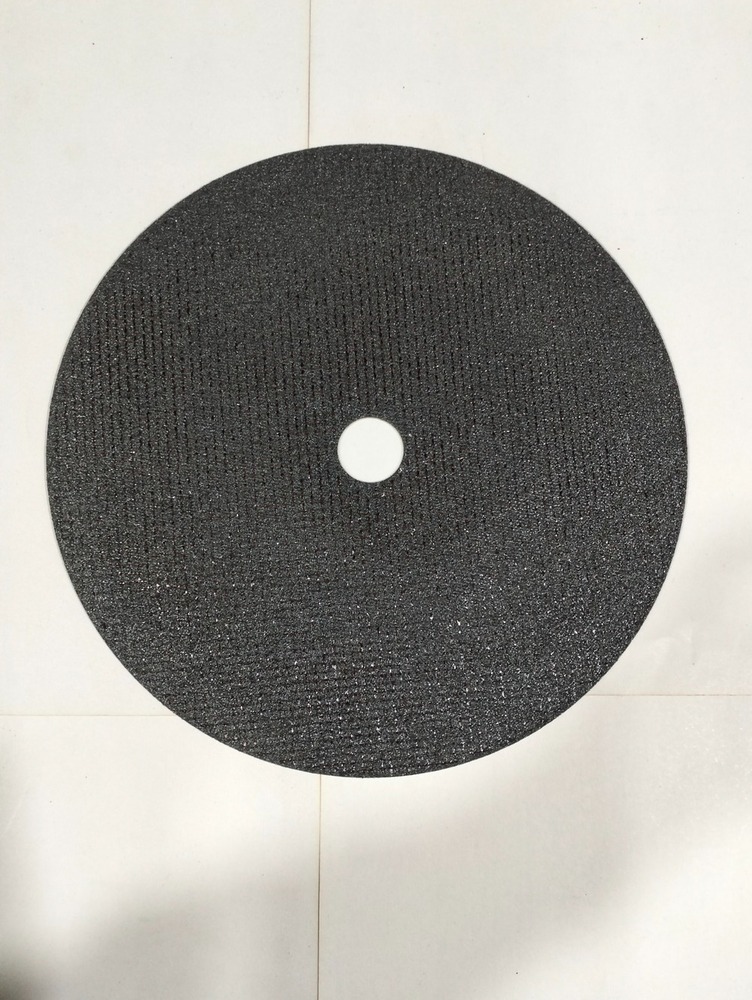

CUT OFF WHEEL

Price 52.00 INR/ Piece

CUT OFF WHEEL Specification

- Hardness

- HARD

- Shape

- ROUND

- Usage

- IRON AND STEAL CUTTING

- Material

- Carbide, High Speed Steel, Tungsten Cobalt Alloy, Steel, Hard Alloy, Tungsten Carbide, Stainless Steel, Alumina, Metal, Carbon Steel, Chrome Vanadium, Cobalt Alloy

- Size

- 250X1.5X25.4

- Height

- 1.5 Millimeter (mm) Millimeter (mm)

- Product Type

- CUTTING WHEEL

- Weight

- 430 Grams (g)

- Rolls Size

- 250MM

- Color

- BLACK

- Length

- 10 Inch (in) Inch (in)

- Width

- 10 Inch (in) Inch (in)

CUT OFF WHEEL Trade Information

- Minimum Order Quantity

- 50 Pieces

- Supply Ability

- 10000 Pieces Per Day

- Delivery Time

- 5 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- 50 PCS PER CARTOON

- Main Domestic Market

- All India

About CUT OFF WHEEL

We are considered to be one of the most important suppliers ofReinforced Cutting Wheelsin the domestic market. In order to fulfill the rising demands of the market, we have come forward to present a capacious range of wheels for our diverse clients. Our offeredReinforced Cutting Wheelsfind wide application in various industries and are fitted in various cutting machines for grinding alloys, mild steel, stainless steel and cast iron.

Features

- Reliable & sturdy construction

- Less heat generation

- Immaculate accuracy

Reinforced Cutting Wheels

We offer high grade of Abrasive Cutting Wheels. These are manufactured by using optimum grade raw material. These are ideal for grinding alloys, stainless steel, mild steel and cast iron. These have great strength reliable sturdy construction high durability. Avail as per specification of client at reasonable market prices.

Unmatched Cutting Performance

Designed for high-efficiency iron and steel cutting, this cut off wheel delivers smooth, precise results every time. The combination of carbide, tungsten alloys, and hard steel provides excellent resistance to wear, ensuring longevity even during high-volume usage. It is an essential addition for workshops and industrial users who demand reliable cutting tools.

Built for Industrial Versatility

With its sharp 1.5 mm profile, 10-inch diameter, and superior hardness, this wheel is perfectly equipped to handle a wide range of cutting tasks. Whether you're working with stainless steel, carbon steel, or other tough metals, its versatile construction allows for consistent, clean cuts with minimal material wastage.

FAQ's of CUT OFF WHEEL:

Q: How should the cut off wheel be properly installed and used for iron and steel cutting?

A: Install the cut off wheel securely on a compatible power tool, ensuring the size (250x1.5x25.4 mm) and arbor match your equipment. Always use appropriate safety gear, and operate at the manufacturer's recommended speed to achieve optimal performance and safety during iron and steel cutting tasks.Q: What types of materials can this cut off wheel effectively cut through?

A: This wheel is engineered to cut through a variety of hard metals, including iron, steel, stainless steel, carbon steel, tungsten carbide, alloys like cobalt and chrome vanadium, as well as high speed steel and alumina, ensuring versatility for various industrial applications.Q: When is it advisable to replace the cut off wheel?

A: Replace the cut off wheel when you notice significant reduction in cutting performance, visible signs of wear, or if the wheel becomes chipped or cracked. Regular inspection prolongs tool life and ensures workplace safety.Q: Where can I source this cut off wheel in India?

A: This cut off wheel is available through authorized distributors, importers, and wholesalers across India. You can contact industrial suppliers or reach out to wholesalers specializing in metalworking tools for bulk purchases.Q: What is the key benefit of using a wheel with a 1.5 mm height for cutting?

A: A 1.5 mm wheel provides precise, narrow cuts with minimal material loss and reduced heat generation, which results in cleaner edges and a lower risk of damaging the workpiece.Q: How does the wheel's hardness and material composition contribute to its performance?

A: The hardness coupled with advanced materials like tungsten carbide and cobalt alloy offers superior durability, resistance to wear, and the ability to sustain high-speed cutting operations, enhancing both efficiency and service life of the wheel.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Reinforced Cutoff Wheels Category

14 CUT OFF WHEEL

Price 85.00 INR / Piece

Minimum Order Quantity : 100 Pieces

Material : Reinforced Resin Bonded (Aluminium Oxide/SiC blend)

Type : Abrasive Cutting Wheel

Shape : ROUND

Color : GREEN /RED/BLACK

10 INCH CUT OFF WHEEL

Price 60.00 INR / Piece

Minimum Order Quantity : 50 Pieces

Material : Reinforced Resin Bonded (Aluminium Oxide/SiC blend)

Type : Abrasive Cutting Wheel

Shape : ROUND

Color : BLACK

7 INCH CUTTING WHEEL

Price 32.00 INR / Piece

Minimum Order Quantity : 200 Pieces

Material : Aluminum Oxide

Type : Metal cutting wheel

Shape : ROUND

Color : Red/Green

Reinforced Cutting Wheels

Price 86 INR / Piece

Minimum Order Quantity : 25 Pieces

Material : Reinforced Resin Bonded (Aluminium Oxide/SiC blend)

Type : Thin Abrasive Cutting Wheel

Shape : Flat, Depressed Center (T41 & T42)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free